ANTI-VIBRATION MOUNTS Products

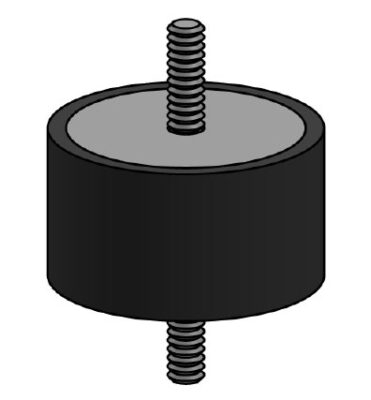

Anti-vibration Mountings

Applications

Used in Engines, Generators as anti vibrators and in heavy Equipments, plants and machineries mainly to isolate vibrations from work surfaces, Reduce noise levels, absorb shock.

Type

Conical mountings, Machine mountings, Bushes, Spherical mountings, Buffer mountings pads, Bobbins, Spring mounts, side bearer mounts, suspension components.

Polymers

Natural, Neoprene, Polyurethanes.

Dimensions

Fully Customised

what are anti-vibration mounts

There is an increasing demand to reduce noise emitted by plant and machinery. The use of vibration isolators is an important part of reducing noise and vibration from industrial and marine plant and from mechanical equipment located in offices, residential apartments, studios, theatres, auditoriums, schools and universities, hospitals and research laboratories and other critical low noise spaces.

Machinery vibration from rigidly mounted equipment can be transferred to the supporting structure and travel large distances to be emitted as noise elsewhere in a building or structure.

Generally, mountings should be selected to provide at least 70% isolation, i.e. no more than 30% transmission, against the lowest disturbing frequency of the system. For static applications, the maximum recommended strain in the rubber is 15% in compression and 30% in shear. Certain rubber-to-metal bonded mountings can also be used in shock applications to absorb energy, and compression strain levels of up to 30% are acceptable in this type of application.

Equipment which is resiliently mounted will have at least one natural frequency – the frequency or frequencies at which it will naturally oscillate. When the disturbing frequency and the natural frequency coincide, vibrations are amplified. The best vibration isolation, therefore, is achieved when the disturbing frequency is significantly higher than the natural frequency.

95%

The aim of vibration isolation is to reduce the transfer of vibration to the supporting structure and a correctly designed vibration isolation system can reduce vibrations by more than 95%.

70%

Generally, mountings should be selected to provide at least 70% isolation.

30%

Certain rubber-to-metal bonded mountings can also be used in shock applications to absorb energy and compression strain levels of up to 30%.

YOUR GUIDE TO MOUNTINGS

AREA OF USE

| AREA | PLATFORM & MOTOR MOUNTS | SANDWICH MOUNTS | LEVELING FOOT MOUNTS | CAPTIVE MOUNTS | CONICAL BUFFERS | RUBBER BUSHINGS | DOUBLE SHEAR BUSHINGS | RUBBER PADS |

| PIPEWORK FITTINGS | • | • | • | • | • | • | • | ✓ |

| BUILDINGS | ✓ | ✓ | • | • | • | • | • | ✓ |

| ELECTRICAL MOTOS | ✓ | • | ✓ | ✓ | • | ✓ | • | ✓ |

| COMBUSTION ENGINES | ✓ | ✓ | ✓ | ✓ | • | • | • | ✓ |

| GENERATORS | ✓ | ✓ | ✓ | ✓ | • | • | • | ✓ |

| HOUSEHOLD EQUIPMENTS | • | • | • | • | • | • | • | ✓ |

| OFFICE EQUIPMENTS | • | • | • | • | • | • | • | ✓ |

| COMPRESSORS | ✓ | • | ✓ | ✓ | • | • | • | • |

| GRINDING MILLS | ✓ | ✓ | • | ✓ | • | • | • | ✓ |

| CHILLERS | ✓ | • | ✓ | • | • | • | • | ✓ |

| FLEXIBLE JOINTS | • | • | • | • | • | • | • | • |

| MOBILE EQUIPMENTS | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| GUILLOTINES | • | • | • | • | • | • | • | • |

| PRESSES | • | • | ✓ | ✓ | ✓ | • | • | ✓ |

| PUMPS | • | • | ✓ | ✓ | • | • | • | ✓ |

| PIPINGS | • | • | • | • | • | • | • | ✓ |

| PUNCHING MACHINES | • | • | • | ✓ | • | • | • | ✓ |

| PRINTING MACHINES | • | • | ✓ | • | ✓ | • | • | ✓ |

| SAW MILLS | • | • | • | • | • | • | • | • |

| ROLLING MILLS | • | • | • | • | • | • | • | • |

| CEILINGS | • | • | • | • | • | • | • | • |

| FANS | • | • | • | • | • | ✓ | • | • |

| MACHINE TOOLS | • | • | ✓ | • | • | ✓ | • | ✓ |

TECHNICAL SPECIFICATION

| SPECIFICATION | Natural rubber | SBR Styrene butadiene rubber | Chloroprene Rubber | Silicon rubber | NBR | EPDM Ethylene propylene diene rubber |

Polyurethane |

| Characterized by flexibility, strength and low temperature resistance as well as Excellent physical properties. Ideal for bonded rubber to metal products. Not Suitable for petrol, grease, oil and ozone. | Similar to natural rubber, resistant to abrasion. Good resistance to high temperatures and cracking. Resistance to extreme low temperatures. Not resistant to petrol, benzene, greases and oils. | All-purpose synthetic rubber, flame resistant. Resistant to abrasion. Very robust, good dielectric strength, particularly recommended for exposure to ozone and weathering. | Silicon exhibits great temperature range capabilities. Silicons also have good resistance to ozone, weather and is also a good insulator. However, it has low tensile, tear and wear resistance. | Resistant to abrasion. Good resistance to high temperatures and cracking, resistance to extreme low temperatures. Good resistance to petrol, greases and oils. | Versatile in use, very good flexibility, resistant to ozone and weather, resistant to low temperatures.Can be used to protect against washing and spraying agents. | Excellent resistance to wear and tear, best flexibility with highest shore hardness of all the elastomers, good resistance to oil and resistant to hydrolysis. | |

| Hardness Shore A | 40 – 90 | 40 – 90 | 40 – 90 | 25 – 80 | 40 – 90 | 40 – 90 | 55 – 98 Shore A |

| Temperature resistance | 40°C to 70°C | 40°C to 70°C | -40°C to 125°C | -70°C to 230°C | -40°C to 120°C | -40°C to 150°C | -30°C to 80°C |

| Short-time peak temperature | 80°C | 80°C | 130°C | 250°C | 125°C | 150°C | 100°C |

| Tensile Strength (Mpa) | 10-26 | 10-20 | 10-25 | 5-15 | 10-20 | 5-20 | 17-38 |

| elongation (%) | 180-800 | 150-750 | 150-650 | 120-750 | 150-750 | 120-500 | 600-390 |

| TEAR NM | 10-100 | 10-70 | 10-60 | 10-18 | 10-50 | 10-50 | 25-60 N/mm |

| ASH CONT% | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 | – |

| S.G. | 0.98-1.2 | 0.98-1.2 | 1.25-1.4 | 1.1-1.2 | 1.1-1.25 | 0.90-1.2 | 1.21-1.18 |

| COMPRESSION SET % | 8-20 | 8-20 | 8-20 | 8-18 | 6-20 | 8-20 | 25-35 |

| RESILIENCE% | high | medium | high | high to low | medium to low | medium | high to low |

| Properties | |||||||

| Abrasion | Excellent | Very Good | Good | Poor | Very Good | Good | Excellent |

| Compression Set | Good | Very Good | Very Good | Very Good | Very Good | Very Good | Good |

| Adhesion to Metal | Excellent | Excellent | Good | Poor | Good | Fair | Excellent |

| Resilience/ Rebound | Excellent | Good | Very Good | Good | Good | Good | Good |

| Dynamic Property | Excellent | Fair to Good | Fair | Poor | Very Good | Very Good | Excellent |

| Electrical Properties | Good | Good | Fair | Excellent | Fair | Good | Good |

| Water Swell Resistance | Excellent | Very Good | Fair to Good | Fair to Good | Good | Excellent | Good |

| Resistance to ozone | Poor | Poor | Very Good | Excellent | Poor | Excellent | Good |

| Resistance to wear/tear | Very Good | Good | Very Good | Poor | Good | Good | Excellent |

| Weathering effect | Fair | Fair | Excellent | Excellent | Fair | Excellent | Moderate |

| Resistance to | |||||||

| Alkali | Good | Good | Very Good | Excellent | Good | Excellent | Fair |

| Acid | Fair to Good | Fair to Good | Fair to Good | Fair to Good | Fair to Good | Good | Fair |

| Alcohols | Good | Very Good | Very Good | Good | Very Good | Excellent | Poor |

| Polar Solvents | Fair to Good | Poor | Poor | Poor | Poor | Excellent | Not Suitable |

| Aliphatic Hydrocarbons | Poor | Poor | Fair | Fair to Good | Very Good | Poor | Poor |

| Aromatic Hydrocarbons | Poor | Poor | Poor | Fair to Good | Poor | Poor | Poor |

| Haloganated Hydrocarbons | Poor | Poor | Poor | Fair to Good | Fair to Poor | Poor | Poor |

| Oils and greases | Poor | Poor | Good | Very Good | Excellent | Poor | Fair |

| Water | Good | Good | Very Good | Very Good | Fair | Excellent | Good |