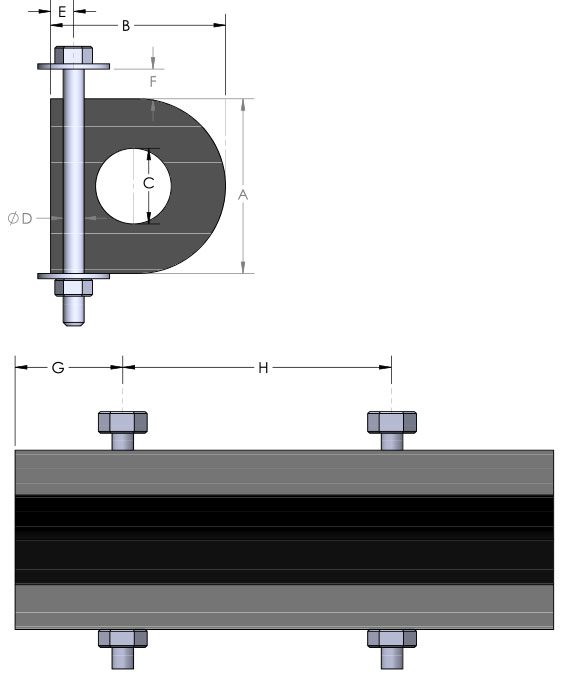

D-O TYPE FENDERS

DESCRIPTION

Ismat manufactures D-Series fenders with either a cylindrical or a “D” shaped bore to provide for varying mounting requirements. Designed for use on tugs and barges, they offer long term durability for applications where repeated compression cycles are encountered in pushing service. They also offer the excellent physical characteristics needed to handle the high loading which occurs both on initial contact, and throughout the service cycle.

DIMENSIONS

| A | B | C | ØD | E | F | G | H | Flat Bar | Bolt Size | Length |

| 75 | 75 | 35 | 10 | 25 | 10 | 100 | 200 | 35×5 | M10 | 3000 |

| 100 | 100 | 50 | 15 | 25 | 10 | 100 | 200 | 50×6 | M12 | 3000 |

| 125 | 125 | 60 | 15 | 30 | 12 | 125 | 250 | 50×6 | M12 | 3000 |

| 150 | 150 | 75 | 20 | 30 | 12 | 125 | 250 | 60×8 | M16 | 3000 |

| 200 | 200 | 100 | 25 | 45 | 15 | 175 | 350 | 80×10 | M20 | 3000 |

| 250 | 250 | 125 | 30 | 50 | 20 | 175 | 350 | 100×10 | M24 | 3000 |

| 300 | 300 | 150 | 35 | 60 | 25 | 175 | 350 | 110×12 | M24 | 3000 |

| 350 | 350 | 175 | 35 | 70 | 25 | 175 | 350 | 120×12 | M30 | 3000 |

| 400 | 400 | 200 | 35 | 80 | 30 | 175 | 350 | 130×15 | M30 | 3000 |

| 500 | 500 | 250 | 45 | 100 | 30 | 200 | 400 | 130×15 | M36 | 3000 |

The above table covers our standard sizes only.

However we can design and build to suit customer’s individual requirements.

All Dimensions in mm. Overall Dimensional Tolerances 35%